● Weighing Systems

● Simon MDS

● Bosch SMP

● Penko

● Machines and Plants

● Dosing Unit

● Raw Material Dosing

● Reference Projects

● Programming

● Coil Handling Station

● Production Line EAMB

● SCADA

● Test Unit for Valves

● Circuit Diagrams - Tests

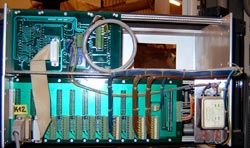

● Switch Cabinet

● Dosing Unit

● S7-300 Danfoss FU

● Siemens C613

● contact

● Deutsche Seite

● Simon MDS

● Bosch SMP

● Penko

● Machines and Plants

● Dosing Unit

● Raw Material Dosing

● Reference Projects

● Programming

● Coil Handling Station

● Production Line EAMB

● SCADA

● Test Unit for Valves

● Circuit Diagrams - Tests

● Switch Cabinet

● Dosing Unit

● S7-300 Danfoss FU

● Siemens C613

● contact

● Deutsche Seite

Conversion of a Penko weighing control unit with Sartorius BATCH-X5A conversion of a Penko weighing control unit, e.g. installed by ter Braak, requires new wiring of the complete dosing controller. In this case ter Braak used 24 V AC voltage as control voltage. The dosing unit BATCH-X5 used for this application needs to be connected to the “old” hardware via connecting relay.The weighing process requires the following dosing functions: - Dosing of liquid components, principally in coarse stream - Dosing of sugar in coarse and fine stream - Starting of agitator 1 and/or agitator 2 during the dosing process of the coarse stream, e.g. for blending in of crystalline components - Starting of agitator 1 and/or agitator 2 for blending as mixing time - With filled storage container: permanent operation of agitator 1 and/or agitator 2 during standby period before receiving the discharge signal - With filled storage container: intermittent operation of agitator 1 and/or 2 during standby period before receiving the discharge signal This exchange option uses the BATCH-X5 equipment as a stand-alone solution.

As a consequence, there is no connection to a PC-controlled recipe and

quantity management system. The data for recipes and components are transfered

into the dosing control system via notebook. Consumed quantities (batch

report and production report) can be printed via serial interface on a

standard printer. |

Batch X5 Front new  Penko Front old  Batch X5 Back new  Penko Back old |